Indonesian biodiesel makers are gearing up to boost exports after the European Union (EU) removed anti-dumping duties on shipments from some producers in the country, but rival suppliers in Malaysia are bracing for a slowdown in the wake of the move. After legal proceedings at the European Court of Justice, the EU last month removed … Read More

Other Bio Equipment

Development problem of biodiesel in the Asian-pacific region

The availability of raw materials is an important factor affecting production capacity. Countries and regions in the Asian-pacific region choose biodiesel materials according to their own national conditions.Malaysia and Indonesia use the country’s abundant palm oil,since palm oil is not a crop, the development of biodiesel will not affect food supplies in both countries.The Philippines … Read More

Philippines promoting biodiesel from coconut

The Philippine Coconut Authority is promoting biodiesel produced from coconut as an environment and engine-friendly renewable fuel for vehicles. Coconut biodiesel is a methyl ester derived from coconut oil. It is produced by the etherification of coconut oil and alcohol in the presence of a base catalyst. Due to its high solvency and lubricity, the … Read More

Advanced Biofuels Canada continues to expand

Advanced Biofuels Canada (ABFC) has announced a significant expansion to its membership. (more information about biodiesel ,pls click!) ABFC is the industry association for biofuels in Canada. According to a statement, the new members include fuel distributors, global technology developers and strategic compliance services providers. These include Canada Clean Fuels, Canfor Pulp, EcoEngineers and Honeywell … Read More

Biodiesel Manufacturing Plant – Continuous Tubular Reactor

Biodiesel Manufacturing Plant – Continuous Tubular Reactor Tubular reactor having a large heat transfer area, high pressure, simple structure, easy processing characteristics. Continuous operation is more, large capacity, easy to implement automatic control, manpower savings, turbulent operation also has good mass transfer at the time of highly exothermic reaction and high pressure, there is no … Read More

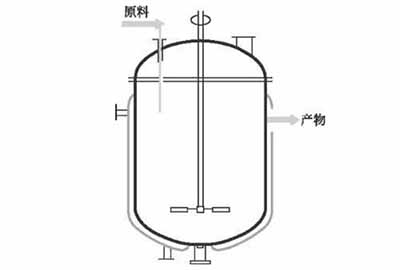

Biodiesel Manufacturing Plant – The Continuous Tank Reactor

Biodiesel Manufacturing Plant – The Continuous Tank Reactor Tank reactor continuous operation, also known as a full hybrid operation, as follows: Which is characterized by the time the material enters the reactor immediately with the inner filter material uniformly mixed, and the same parameters temperature inside the reactor, concentration and other parameters and export of … Read More

Biodiesel Manufacturing Plant – Intermittent Reaction Device

A liquid fuel biodiesel is obtained by switching from vegetable oils, animal fats or fatty alcohol esters with a single reaction. Trans-esterification reactor is the core equipment of biodiesel production process, product quality and production costs, production energy consumption and impact on the environment has a decisive role. Select the correct form, structure, size of … Read More

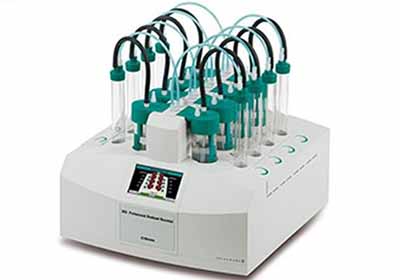

Professional Biodiesel Rancimat

The biodiesel equipment professional biodiesel rancimat determines the oxidation stability of biodiesel (fatty acid methyl esters, or FAME for short) and biodiesel blends. In the Biodiesel Rancimat, increased temperature and a continuous stream of air through the sample accelerate its aging. The time that passes until oxidation takes place at a high rate – the … Read More

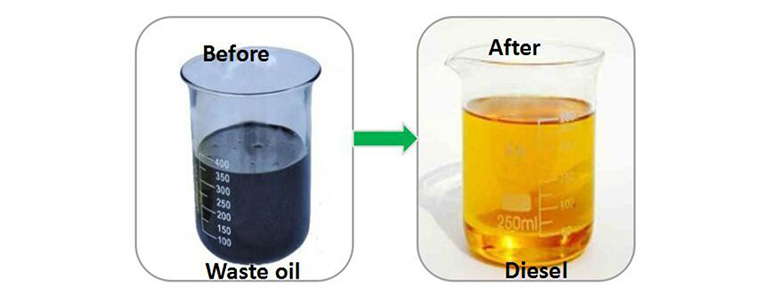

Machine Making Tire Oil Or Plastic Oil To Biodiesel

The oil purifying or distillation equipment is applied to recycle the waste liquid oil (such as waste engine oil, waste crude oil, tire or plastic oil after pyrolysis) into non-standard gasoline and diesel. It mainly includes 1) oil distillation kettle, 2) rectifying tower, 3) oil-gas cyclone sedimentation tank, 4) condensation system, oil storage tanks, 5) … Read More

Biodiesel Oil Disc Centrifuge Separator

Biodiesel disc centrifuge has advantages such as high speed, stable operation, closed inlet and outlet systems, low noise, good separation effect, etc. Centripetal pump system has features including stable output pressure, large adjusting range, convenient operation, and so forth. The machine is widely used in degumming, desoponificating, washing, glycerine separating and other techniques in biodiesel.