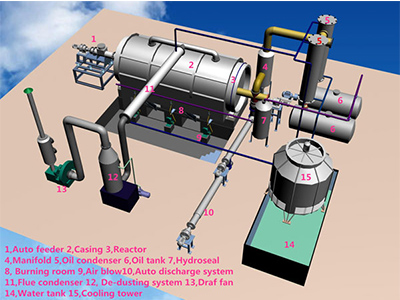

Daily capacity: 10 MT Average output rate: 50% Reactor size: D2.8*L6.2 m Operation Pressure: normal pressure Material of reactor: Q245R boiler steel Space for machine(L*W*H): 25*15*10 m Reactor plate thickness: 16mm Rotary speed: 0.4-0.8 turn/min Power: 30 kw/h Life time: 5-8 years The plant can deal with many waste materials, such as waste plastics, … Read More

Pyrolysis Equipment

Waste Sludge Oil/Tire/Plastic/Rubber Process Pyrolysis Plant

24-capacity: 10MT Input-Raw materials: Waste Sludge Oil /Tire/Plastic/Rubber Operating pressure: Constant pressure Maximum height: 9meters Steel thickness of reactor: 16mm Reactor rotate speed: 0.4 turn/minute Power in total: 30kw/hour Reactor size: Ø2200*6000*16 mm Life time: 5-8years Recycling Pyrolysis Plant For Sludge is a processing unit that makes use of pyrolysis of massive scrap tyre/plastic/rubber/oil … Read More

Efficient Atomization Desulfurization Dust-Removal Device

Efficient,durable, low cost, easy management, low maintenance Usage: Removing sulfur dioxide, nitrogen oxides, fluorides and other harmful gases while removing dust. Features: As the dust collector removes sulfur dioxide, nitrogen oxides, fluorides and other harmful gases while removing dust, which are electrostatic precipitators and bag-type dust collector such dry collectors cannot reach. Efficient atomization desulfurization … Read More

Static And Dynamic Seals For Pyrolysis Plant

Plasticity, easy maintenance, low cost Usage: Sealing connection between the dynamic device and static equipment. Features: Static and dynamic seals have a good enough plasticity and high strength, easy to weld, good corrosion resistance, can withstand the cold and hot pressure processing, easy maintenance, sealing parts can be found easily. Due to thermal expansion and … Read More

Multi-Stage Separator For Pyrolysis

Wide range of applications, low power, low cost and not easy to damage Purpose: The main function of multi-stage separator for pyrolysis is possible to remove solid particles impurities and droplets entrained in the gas and achieve to the gas-liquid separation in order to ensure the normal operation of pipelines and equipment Features: It is a … Read More

Water Seal System For Pyrolysis

Simple, efficient and easy to operate Purpose: To prevent the system from non-condensable gas contact with outside air, and prevent the burner of tempering, which can effectively avoid the happening of the accident. Features: Using water as medium, effectively blocking the process of the combustible gas and combustion section of links, and also effectively neutralize … Read More

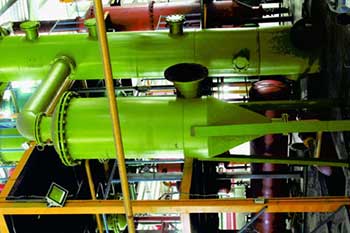

Horizontal Rotation Cracking Furnace

Advanced technology, little pollution, low production costs Purposes: Organic solid waste pyrolysis. On the design of the key device for cracking furnace, our company thoroughly overcomes the domestic current vertical partial uneven heat cracking furnace bottom, easy to fracture, low yield, short service life of unfavorable factors. Features: (1)Using no-stripping technique, which does not require … Read More