Introduction Biodiesel production does not result in a lot of waste. However, depending on the process and feedstocks use, it can produce some wastewater, minerals, resins, solids strained out of used oil and glycerin. Often, waste is not an issue for large producers because they can invest in the equipment needed to recycle and reuse … Read More

Biodiesel Manufacturing Plant

Commercial and Large Scale Biodiesel Production Systems

Introduction Commercial-scale biodiesel producers have many constraints beyond those which small producers need to meet. Commercial producers must satisfy the expectations of owners and/or stockholders for profitability. They must make optimal use of capital and other resources. They also have to include the cost of labor because it comes from paid employees. Small-scale producers will … Read More

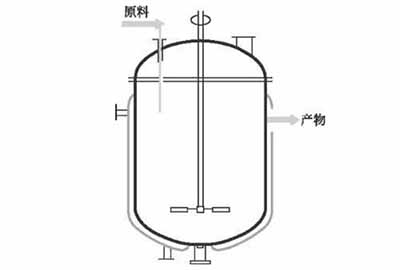

Biodiesel Manufacturing Plant – The Continuous Tank Reactor

Biodiesel Manufacturing Plant – The Continuous Tank Reactor Tank reactor continuous operation, also known as a full hybrid operation, as follows: Which is characterized by the time the material enters the reactor immediately with the inner filter material uniformly mixed, and the same parameters temperature inside the reactor, concentration and other parameters and export of … Read More

Biodiesel Manufacturing Plant – Intermittent Reaction Device

A liquid fuel biodiesel is obtained by switching from vegetable oils, animal fats or fatty alcohol esters with a single reaction. Trans-esterification reactor is the core equipment of biodiesel production process, product quality and production costs, production energy consumption and impact on the environment has a decisive role. Select the correct form, structure, size of … Read More