When tire pyrolysis and recycling, you will have a problem that tires is thick and hard to curve, so before feeding the waste tires into reactor, it is better to cut the tire sides down. So we can know Tire cutting is the important step before tire pyrolysis and recycling, Besides, this part of tire has good value, circle cutting machine helps collecting these thick steel wires.

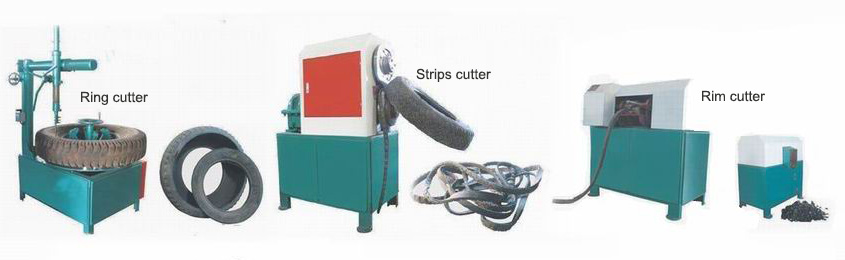

There are three different Tire Cutting Machine following: Cutting Circle Machine, Cutting Strip Machine and Cutting Block Machine.

Cutting Circle Machine

Cutting Circle Machine

Technical Parameters:

Power : 2.2KW

Size of tires: ≤φ1200mm(OD)

Size: 1480×1469×1200mm(L×W×H)

Application:

1. Low consumption, light in weight, occupying a small area are also the traits of the machine.

2. The tire is easy to be installed, with a short reciprocating stroke, and the machine is productive.

3. The feeding cutter is made of excellent high rigidity wearing proof alloy steel, the service life of the machine is long, and the tool grinding can be repaired by resurfacing welding repeatedly.

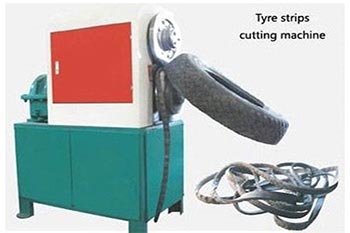

Cutting Strip Machine

Technical Parameters:

Power: 4KW

Size of tires: ≤φ1200mm(OD)

Size: 1330×700×1580mm(L×W×H)

Application:

Cutting strips machine is used with circle cutting machine and could cut the tires without tire sides into strips. Rubber strip cutting machine as the primary part of waste tire recycling line, which can makes the whole waste tire into strips in order to improve the efficiency.

Cutting Block Machine

Techinical Parameters:

Power 7.5KW

Size of tires ≤φ1200mm(OD)

Size 800×800×1060mm(L×W×H)

Application:

Waste tire block cutting machine is utilized to process the rubber stripes into rubber blocks with a certain size, which is good for latter production and improving work efficiency. It is generally used along with bar cutter, and it is essential equipment for waste tires processing.

Features:

1.Operators and machine are separated when working, easy and safe operation.

2. High efficiency, less labor.

3. Low energy consumption, which can save more cost.

4. Quality assurance can satisfy continuous production.

5. Cutters are made of high-quality strength wear-resistance alloy, long service life.

6. Lower cost maintenance. Machine is widely used and can be matched with all kinds of waste tire recycling line.