Model: BZJ-06

Model: BZJ-06

Capacity/D: 6T

Raw Material: Crude oil, Waste oil, Fuel oil, Used engine oil

Heating material: Oil, LPG, Natural Gas, Wood, Coal,etc

Structural Form: Vertical

Oil Yield Rate: 80%-90%

Power: 20KW

Cooling Mode: Water Cooling

Life Time: more than 7 years

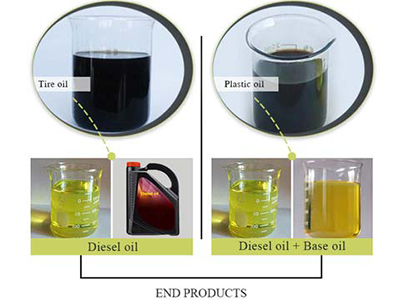

The used oil mainly includes the recycled engine oil , crude oil, waste oil, fuel oil, and the pyrolysis oil which is produced by using the pyrolysis technology to process the waste materials, such as waste plastic, waste tyre, waster rubber and oil sludge. To reprocess the waste oil, and make them have a higher purity, we can use used oil distillation plant to turn them to diesel.

BZJ-6 waste oil refining plant, Capacity 6MTPD, which can be operated in normal pressure condition and vacuum pressure condition. Latest hot air heating system, which can increase reactor’s life time for extra 1-2 years. Total sealed distillation reactor and distillation tower before it gets into condensers and liquefied into light fuel oil. This kind of oil will be piped into deep purifying system with acidity and alkaline cleaning devices as well pressure filtering system. Then we get diesel oil that can be used in engine and generators

Main component systems of used oil recycling plant and their functions:

1. Pre-treatment device for raw material: waste oil is fed into refinery boiler after pre-treatment.

2. Refinery system: heat the waste oil to working temperature by using fuel oil, gas, coal etc. as heating materials. In the meanwhile, there are stir system and heat preservation system.

3. Cooling system: cool the gaseous hydrocarbon into diesel.

4.Interim storage system: base oil and diesel after cooling are stored here, and then put into oil tank.

5. Vacuum system: to meet the process required.

6. Filter system: rapidly filter mechanical impurities in the diesel produced, and got qualified diesel.

Advantages of used oil recycling plant:

1. Safe

The pressure release device operates through water circulation, which greatly improves the security of the system. Equipped with thermometer, pressure gauge, safety value and electric control system, the machine can avoid danger in the production process.

2. Environment-friendly

The machine adopts three-layer dedusting system to cleanse the exhaust gas to reach European pollution control standards. The complete set of unit produces no smoke and smell with favorable effects of environmental protection.

3.High-quality and high-efficiency

New-type tubular condensers, larger cooling area, better cooling effect and higher oil yield.

Parameters data of Used Oil Recycling Plant:

| used oil recycling plant: | |||||

| Batch Operating Plant | Auto Continuously Operating Plant | ||||

| Model | BZJ-06 | BZJ-10 | BZL-25 | BZL-50 | BZL-100 |

| Raw material | Crude oil, waste oil, fuel oil, | Crude oil, waste oil, fuel oil, | |||

| used engine oil | used engine oil | ||||

| Structural form | Vertical | Vertical | Vertical | Vertical | Vertical |

| 24-hour handing | 6MT | 10MT | 25MT | 50MT | 100MT |

| 24-hour oil yield | 5.1 MT | 8.5 MT | 21.25 MT | 42.5 MT | 85 MT |

| Operating pressure | Normal and Vacuum | Normal and Vacuum | |||

| Heating material | Oil, LPG, Natural Gas, Wood, Coal,etc | Oil, LPG, Natural Gas, Wood, Coal,etc | |||

| Power | 20kw | 36kw | 138kw | 178kw | 178kw |

| Model of cooling | Water cooling | Water cooling | Water cooling | Water cooling | Water cooling |

Application of end product:

We can get diesel oil with high purity after refining by distillation machine, this kind of oil can be used for tractors, trucks, ships, and diesel oil generator etc.