Model: BZJ-10

Model: BZJ-10

Capacity/D: 10T

Raw Material: Crude oil, Waste oil, Fuel oil, Used engine oil

Heating material: Oil, LPG, Natural Gas, Wood, Coal,etc

Structural Form: Vertical

Oil Yield Rate: 80%-90%

Power: 36KW

Cooling Mode: Water Cooling

Life Time: more than 7 years

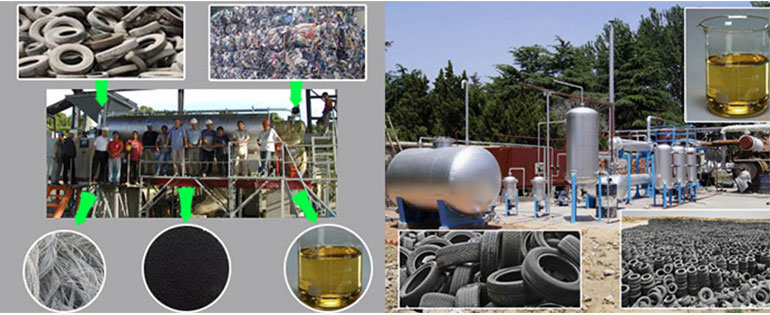

Green distillation technology is aimed to turn crude/waste oil to diesel. We use the pyrolysis technology to get fuel oil from waste tire, and then refine the crude oil into diesel oil with the distillation technology, which could better solve the oil resources decreasing problem while disposing of the waste.

10MT/D Capacity, which can be operated in normal pressure condition and vacuum pressure condition, latest hot air heating system, which can increase reactor’s life time for extra 1-2 years. Totally sealed distillation reactor and distillation tower before it gets into condensers and liquefied into deep purifying system with acidity and alkaline cleaning devices as well pressure filtering system. Then we get qualified diesel oil that can be used in engine and generators.

The process of tyre pyrolysis oil distillation:

the oil will first be pumped into the reactor and then it will start to boil and evaporate when it is heated to the working temperature. Oil gas from reactor has already been purified by distillation tower before it gets into condensers and liquefied into light fuel oil. This kind of oil will be piped into deep purifying systems with acidity and alkaline cleaning devices as well as pressure filtering system. When the whole distillation process is over, we will get qualified diesel oil or gasoline, the performance indexes (density, viscosity, acid value) of which can meet new standard data

Main features of the tyre pyrolysis oil distillation plant:

1. Automatic feeding and discharging systems, which makes it easy to operate and can greatly save manpower.

2. Totally sealed distillation reactor and distillation tower to avoid gas leakage and ensure no-pollution.

3. Latest hot air heating system, which can prolong the service life of the reactor for extra 1-2 years.

4. New-type tubular condensers, larger cooling area, better cooling effect and higher oil yield.

5.Equipped with safety valves, automatic alarming system, anti-explosion valve, which will guarantee 100% safety in the working process.

6. Adopting three-layer dedusting system to cleanse the exhaust gas, the released gas will reach European pollution control standards.

Note:

Machine for waste oil recycling adopt anaerobic or poor oxygen pyrolysis technology. Feeding and discharging auto sealing operation, material under the anaerobic or poor oxygen condition proceed pyrolysis reaction, smoothly process and totally and completely. so if you have plan to refining waste oil, Contact Us to give the opportunity to communicate further.

Technical data of tyre pyrolysis oil distillation:

| Waste oil distillation plant | |||

| Batch Operating Plant | Auto Continuously Operating Plant | ||

| Model | BZJ-06 | BZJ-10 | BZL-25,BZL-50,BZL-100 |

| Raw material | Crude oil, waste oil, fuel oil, used engine oil | ||

| Structural form | Vertical | ||

| 24-hour handing | 6MT | 10MT | 25MT,50MT,100MT |

| 24-hour oil yield | 5.1 MT | 8.5 MT | 21.25MT,42.5MT,85MT |

| Operating pressure | Normal and Vacuum | Normal and Vacuum | Normal and Vacuum |

| Heating material | Oil, LPG, Natural Gas, Wood, Coal,etc | ||

| Power | 20kw | 36kw | 138,178,178(kw) |

| Model of cooling | Water cooling | ||

Application of end products:

We can get diesel oil with high purity after refining by distillation machine, this kind of oilcan be used for tractors, trucks, ships, and diesel oil generator etc.